What is?

An HMI is nothing more than the interface, which will make the interaction of man or user with the machines or processes that are part of an automation. Thus, the acronym HMI stands for Human Machine Interface or HMI (Human-Machine Interface).

These interfaces, commonly applied in industries, are robust hardware that is super protected against collisions, water, excessive force, etc. This is because they were created for factory floor, ie aggressive environment. Considering this, they are mainly composed of a screen that can be touch screen, as if it were a large reinforced tablet. Some even come with a keyboard and / or PLC attached. On the other hand there are interfaces (HMI) that have neither processor nor. Thus, they work simply as mere transmitters of information.

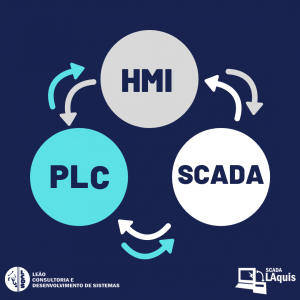

Generally, the HMI communicates only with the PLC and the SCADA system interacts with the PLC, but there are applications where the interactions between HMI and SCADA may occur.

How they work

HMIs, the most complete with processors, are almost like a computer with an interface. Some even have specific operating system (Windows has versions for this, for example), others don’t even need OS. In them is executed the application, developed by the SCADA system. They can have USB, ethernet, VGA output, audio output, RS-232, RS-482 or RS-485, etc. This may seem a bit confusing, but it will be clear from the example below, where we will show an example application / panel for HMI programming, where the machine operator will access the device and can: monitor the machine’s operation and interact with it.

Some advantages of using HMI

- Quick and low cost to meet changing environment

- Multi touch screens

- Connected systems and mobile access to HMIs

- Cost reduction, wiring and energy use

- Portable and easy to deploy in industrial environments

- Better command and control capability

- Easy operation

Application Examples

- Alarm Display

- Parameter Change

- Some equipment configuration changes

- Speed adjustment

- Perform manual movements