Supervisory is a type of software for "supervisory control and data acquisition". LAquis supervisory includes everything from the interface, report generation and development of specific applications.

SCADA supervisory systems gather and control data from a wide range of equipment spread throughout the industry in real time. These devices are generally used in industrial automation. Then, using the stored historical information, the supervisory systems generate statistical reports for process optimization and quality control. Supervisory systems allow monitoring of equipment information in the industry in real time and generating statistical reports to improve automation management in the industry, optimize production and simplify the user process.

LAquis Supervisory

Supervisory Control and Data Acquisition (SCADA) software.

Tool and language for data acquisition, process supervision, industrial automation, storage and report generation. Supervisory with 3D and WEB interface options.

Download - LAquis Supervisory System

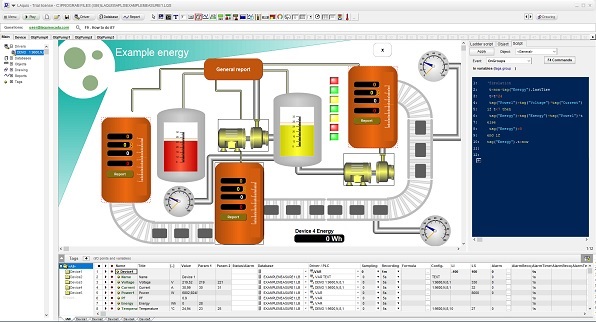

Equipment used to communicate with the supervisory system is usually PLCs. Each PLC has a list of input and output variables to control the process and automation. The supervisory system can read and control these variables as needed. Communication between the supervisory system and the automation equipment is done through drivers that interpret the information according to each protocol. The communication medium can be RS232, RS485, Ethernet, wireless, etc. One of the protocols used is MODBUS RTU/TCP. Supervisory systems can also be equipped with a user screen or HMI (human machine interface). In this HMI on supervisory systems, visual objects monitor and control equipment information.

Displays, gauges, graphs, LEDs, figures, animations, data inputs, etc. The data in the system can be stored in a historical database. This database can contain several tables where process information is managed. Using this data recorded by the supervisory systems, reports can be generated by the system. These reports can contain tables, graphs and calculations. Each format can be customized according to the standard or quality control. In specific applications, the supervisory system has a script language. This language allows the supervisory system to customize actions in industrial automation according to each process. The supervisory system data can also be distributed via network from a server to be monitored by other clients.

Basic applications:

Indicate, in the tag spreadsheet (input and output points), equipment, addresses, variables, properties, input and output data, files, etc. The supervisory software will be ready to read or control values and, from the stored data, generate customized reports according to the automation needs. Monitoring, storage, history, access to hardware, generation of reading reports, network monitoring, etc. are some of the basic features of this supervisory software.Each variable, "tag", reading or writing point in the supervisory system can contain as many properties as necessary. Likewise, the files used to record data are also flexible; their fields can be defined by the user in the supervisory system.

Reports:

The LAquis supervisory system also has special report generation resources. In addition to the models already available in the system, it is possible to develop everything from simple reports to statistics focused on automation, inspection and quality control. The information inputs and outputs are flexible in the supervisory system. Using visual spreadsheets, graphs and script language, customize reports according to the needs of the industrial automation application.Advanced applications:

The LAquis supervisory software offers the possibility of programming using a structured visual language for supervision and industrial automation. Use visual controls to customize the system. Program actions and events using this language.WEB interface: Monitor the supervisory system via the Internet/Intranet/WEB.

Communication drivers can be developed in the LAquis supervisory software itself. LAquis has a language focused on this type of development (ldriver). In addition, it is possible to create drivers for the system using scripts or DLLs. The LAquis supervisory software also supports receiving tags via OPC. (The demonstration below has some drivers included - example MODBUS.ldriver)

LAquis 3D Supervisory Software: Draw the plan and define the controls. The system automatically generates a 3D interface.