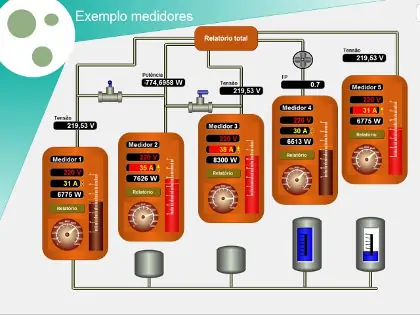

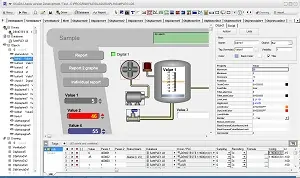

Create SCADA HMI visual panels with objects associated to tags.

SCADA Software

Supervisory Control and Data Acquisition

SCADA meaning

SCADA definition is Supervisory Control and Data Acquisition.

SCADA systems are used mainly for industrial automation data acquisition and process control using PLC technology

or RTU equipment with communication in a distributed control system (DCS) inside the industrial control system (ICS). This technology assists the management of the industrial process in real-time.

In the SCADA software, a user interface is designed in a computer for monitoring and controlling the process. Customized reports can be generated with the storage data to show the calculus and statistical information of management and the quality of the process.

SCADA systems must have a high level of security. Security is an important issue within SCADA software, so that both the network and the system have protections over the industrial process.

They gathers the industrial equipment network data in real time and provide monitoring, alarms and statistical and quality reports. Each project can be edited by a user or designed by an engineer.

These process data can be also distributed in the computer network using the industrial internet of things (IIOT) concept.

Click here to download the SCADA software: Download

SCADA software

SCADA software is the monitoring and control program, developed on the computer. It has an interface, which can be designed in a personalized way, and which helps in the management of industrial production, equipment testing, water treatment and monitoring. In addition to the interface, it also has statistical reports.

Examples here: SCADA programming examples

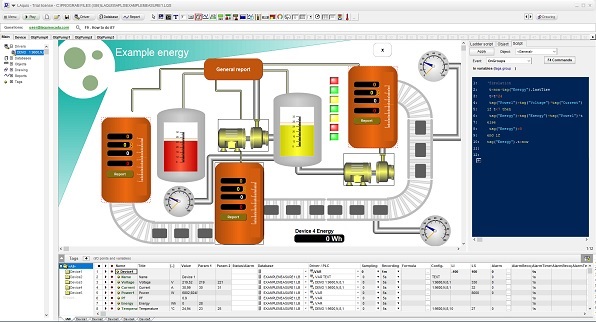

LAquis SCADA system solution is a tool and language software for data acquisition, control, process supervision, automation, storing, reports generation and applications development. LAquis is a SCADA software. Set tags (I/O points), equipment (modules, devices, PLC, IIOT, ...), DCS (distributed control system), variables, databases, customizable properties, HMI SCADA visual interfaces, customizable reports until advanced processes through a script programming language oriented to industrial automation. Download.

Communication PLC drivers can be developed in the SCADA software itself with a language oriented to driver development (ethernet or serial).

Communication drivers are software libraries designed to control the devices that send and receive frames to the equipment and get or set information based on each protocol in real time.

It is possible to create or edit drivers for equipment and PLC in the SCADA software through scripts programming, external DLLs or OPC.

Each driver depends on each equipment industrial protocol. Some drivers are already included in the SCADA software such as MODBUS (TCP or RTU), Alnet, Advantech, DF1, Omron, etc...

SCADA MQTT are used with this MQTT protocol for telemetry. The software use a server or broker that assists in communication.

Several types of communications in the software, temperature, counts, alarms, pressure, humidity, energy, electrical power, length, levels, water treatment, etc.

SCADA temperature monitoring software is also used for the environment, for example, in the food industry.

There is also a 3D interface feature to edit in the SCADA software: transform 2D factory plan into a 3D OpenGL interface with visual objects associated with PLC variables. The objects may be created in the supervisory software itself or imported from other systems.

LAquis SCADA software solution is used to control industries and business systems like: food, textile, metal, electric, manufacturing, oil and gas, automotive, security, agronomy, energy, wood, inspection, hydraulic, chemical, paper, water treatment, etc...

Get tutorial for SCADA training.

Click here to download the SCADA software: Download

Introduction:

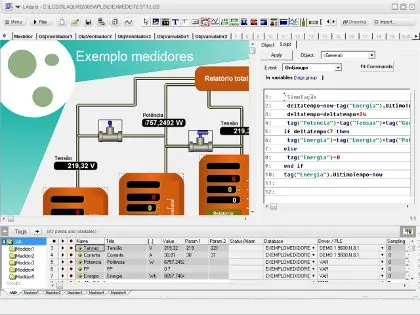

The main HMI SCADA screen at development programming mode is divided into two parts: the bottom where there is a spreadsheet with the PLC variables and the top panel where visual HMI objects are placed to control data in real time.

In runtime mode panels can be set to full screen.

A full application, designed by a user or engineer, can be developed through windows and panels, from the HMI SCADA to reporting, with the data acquisition and process control.

Factory plants, control systems, screen panels navigation, web, etc... panels may be created to specific cases.

The main HMI SCADA screen at development programming mode is divided into two parts: the bottom where there is a spreadsheet with the PLC variables and the top panel where visual HMI objects are placed to control data in real time.

In runtime mode panels can be set to full screen.

A full application, designed by a user or engineer, can be developed through windows and panels, from the HMI SCADA to reporting, with the data acquisition and process control.

Factory plants, control systems, screen panels navigation, web, etc... panels may be created to specific cases.

Tags:

In this SCADA software, IN and OUT points variables can be edited in a PLC tags spreadsheet to control the whole process in the supervisory system.

Properties like equipment, PLC, variables, files, formulas, scales, etc... are defined for each case.

Theses tags data can be stored in the SCADA database continuously or through systems events with security.

They may be associated with the visual objects and reports.

Limits can be defined for each tag state generating alarms.

Formulas are used to calculate values for the data and define scales in the SCADA software.

And to advanced cases, script programming can control these PLC variables.

To specific cases, there is a possibility to create customized properties. The access to this variables must be protected from unauthorized users through the SCADA system security. Download LAquis SCADA

Objects:

On the HMI panel, visual objects may be used in the system both to control specific systems and also for simple data monitoring in real time for supervisory purposes.

These objects can be developed inside the SCADA software or imported from other software. Some these objects are available with source for free.

Each object can control the information from the defined variables in the tag sheet.

It is possible to create and modify objects drawing with vector objects to specific cases.

There is also an option for object script development system with open source SCADA solutions.

Each object has properties and events that may be configured.

Some of these objects can be exported to WEB monitoring with security protection.

Programming scripts:

Scripts can be used in the SCADA software processes programming to create specific applications using objects, PLC tags, databases and reporting.

They are used to control tags behavior according to each process. There are several commands oriented to industrial automation.

This script is a language for software development for windows 32 platform.

Scripts may be executed inside events from objects or process. The security of the script language is also important to prevent unauthorized actions.

Database:

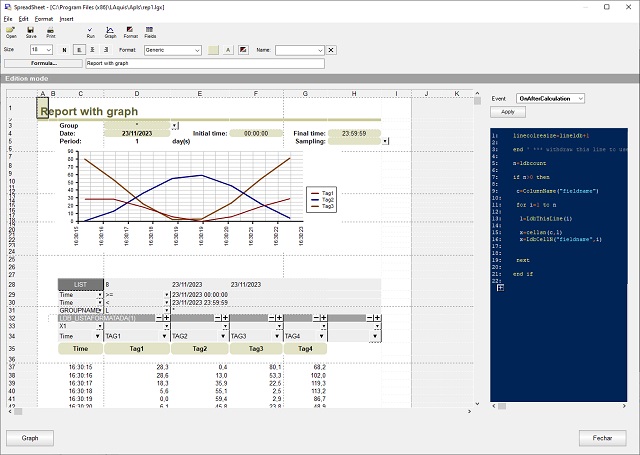

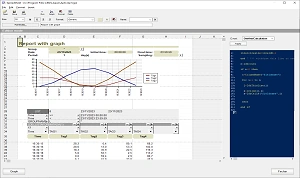

When setting a database in the tags spreadsheet, reports can be generated from the stored data acquisition for quality management, analysis, and charts with stored history information.

These reports can be modified according to each case with a generic spreadsheet with cells, calculus and database listing.

This spreadsheet is customized with database and formulas.

Templates are also available to generic industrial needs and can be also modified.

Scripts are used inside reports to create specific SCADA applications using calculation and analysis. The security of the database is also important to protect the data.

When setting a database in the tags spreadsheet, reports can be generated from the stored data acquisition for quality management, analysis, and charts with stored history information.

These reports can be modified according to each case with a generic spreadsheet with cells, calculus and database listing.

This spreadsheet is customized with database and formulas.

Templates are also available to generic industrial needs and can be also modified.

Scripts are used inside reports to create specific SCADA applications using calculation and analysis. The security of the database is also important to protect the data.

Monitoring:

The SCADA also monitors the data through an integrated computer remote network in a distributed industrial control system (WEB or directly via TCP) in real time.

Some objects are exported to HTML if WEB control is needed, and in this case, the SCADA software become a WEB server in parallel to the desktop system.

A remote supervisory desktop version can be used without WEB using TCP.

Exports visual objects and panels and reports and distribute to the PCs in the plant network system. The monitoring data must be allowed only to authorized users in the SCADA security.

Click here to download the SCADA software:

Download

Security:

SCADA security control is an important item to secure access to the industrial information.

The industrial control system network, for example, must be controlled and can not allow unauthorized access.

The SCADA systems must prevent this. There is a continuous work on mitigate security issues in the SCADA system as reported by ICS Cert advisories.

Architecture:

The project, defined by the engineer, can be specific for each case.

Set the PLC I/O points variables or IIOT addresses on the tags spreadsheet at the bottom of the main screen.

These variables may be generic or physical equipment data variables.

Their values are numeric, text or digital.

Data that come from equipment are transmitted using a several types of communication protocols according to specific systems.

They are customizable according to each SCADA process.

Some variables are defined by formula, association and script.

Limits are also specified to control alarms.

The PLC tags spreadsheet contains properties to control what will be read or written on the equipment by the SCADA system.

These properties are also customizable.

Some of the main properties are: Name, Title, Value, Unit, Driver / PLC, Database, Param1, Param2, Status, Formula, Limits, Alarm, custom, etc ....

Each property can be a column in this PLC variables spreadsheet.

Some columns are customized and added according to the application system.

Choose the equipment driver to be used in the SCADA software in the Driver / PLC column.

The driver can be set by dragging the mouse pointer with the left button on the Driver / PLC column, or by clicking on the Driver / PLC column title to select all tags desired at the group.

Driver is the library that performs the communications with the equipment / PLC or specific function. Some of them are timers, clocks, scripts, sine functions, etc...

These properties are also customizable.

Some of the main properties are: Name, Title, Value, Unit, Driver / PLC, Database, Param1, Param2, Status, Formula, Limits, Alarm, custom, etc ....

Each property can be a column in this PLC variables spreadsheet.

Some columns are customized and added according to the application system.

Choose the equipment driver to be used in the SCADA software in the Driver / PLC column.

The driver can be set by dragging the mouse pointer with the left button on the Driver / PLC column, or by clicking on the Driver / PLC column title to select all tags desired at the group.

Driver is the library that performs the communications with the equipment / PLC or specific function. Some of them are timers, clocks, scripts, sine functions, etc...

The data acquisition from the PLC tags may be recorded to a file (database). This database is a flexible and customizable set of fields and records of the SCADA process. Each field can be a tag or generic value of the process. Data types are float, integer, text, byte, datetime, etc... Database may be proprietary binary files, dbf or text. Click on the database column. The database can be set by dragging the mouse pointer with the left mouse button on the database column (like it was done with the driver), or by clicking on the title of the database column to select all tags desired at the group. Data recorded from the SCADA software are used in reports through the button Report. They are designed using a spreadsheet with functions and script oriented to database. A visual objects panel is located on top of the main screen. On this panel, objects and visual controls are designed and can be used as the interface for the user. These objects can be displays, pictures, animations, controls, etc... They are associated with the tags. They can be designed in the SCADA software through vector drawings, script or imported from pictures. These objects are placed on the panel.

The panel is divided into pages/windows. Each page is selected according to each case.

Vector object drawings also can be controlled by tags. Executable applications present to the user the designed HMI interface system.

Specific applications can be also developed through scripts for several kind of SCADA systems. They are executed within the available events in the SCADA software. Each object and process has events. Scripts are placed inside these events.

Clicks, scanning, alarms, tags, etc...

Scripts are sequences of instructions or programs used to customize the application's actions to control the process.

This language is compiled in real time. Data from the PLC tags are accessed and controlled through scripts. The commands are oriented to industrial automation processes.

Example:

If Tag1 > Limit Then

Tag2 = 1

End If

It is possible to access and control every SCADA tag and its properties through script with security.

There are also specific controls in the security area, an important issue for the SCADA software.

Click on tutorial for training.

Click here to download the SCADA software:

Download

Customize SCADA reports according to each application. Quality management: alarms, nonconformance tracking, ISO standard flexible and customizable reports, etc...