Communication Types

Types of communication system:

- RS-232 serial

It is one of the most economical options, but they are used for short distances. Uses 4 to 6 wire cable with DB9 connector. It has capacity for only one equipment.

- Serial RS-485

Another more economical option. The cable has only 2 wires, commonly applied in industries. The distance can be up to 1Km and can be connected to several equipments in the same connection system. Optionally can be shielded from electrical noise.

- Ethernet

This is the most expensive option, on the other hand is the faster than those mentioned above. Uses RJ45 network cable. It has capacity for various equipment, routers and Wifi.

Industry

Industrial automation, through the SCADA system, is important to assist in production. It can organize, increase the speed and quality of products. The quantity and production time are usually monitored. There are several other values followed in SCADA in real time that interfere with productivity. These values can be temperature, pressure, humidity, energy, distances, levels, etc. Information from motors, pumps, lights, equipment or relays is also monitored and controlled. Industries may have multiple production lines.

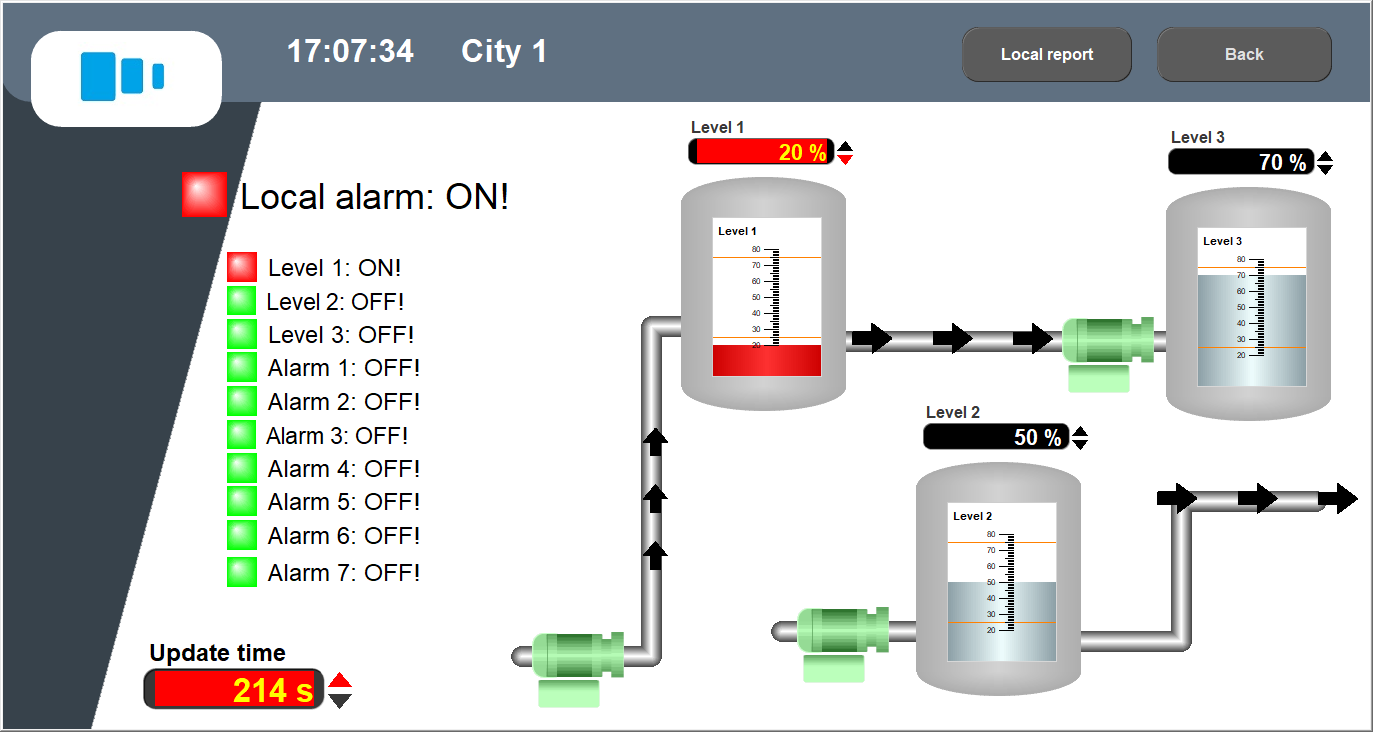

Graphical user interface

The graphical user interface is used to present the industry design or scheme. The screen can be configured with visual objects with device information. Screens are sometimes configured on the computer. The design in the SCADA interface is used to monitor the information. Production lines, for example, can be placed on the screen. Tracks each line and maintains the information.

Data acquisition

Data collected via SCADA is usually recorded in the database. Statistics are used to analyze production quality.

Each day can have specific reports. Production orders organized by systems can be stored in SCADA. Calculations of comparisons of the values read from the instruments are used to evaluate the production results. The SCADA system assists in the acquisition of these data during runtime. In some cases writes the values on the equipment. They can set temperatures or start motors according to the communication protocol.

Quality

It is very important to evaluate the quality of the production, to help in the results of the products.

Generally, a computer is connected to the SCADA and controls and monitors the equipment connected to it in real time. Even in serial or ethernet form, this data is sent and received by the system. There are several examples of ready-made SCADA interfaces. Each industry must have a specific configuration. But there are similarities in the classifications of factory areas.

Companies

Other types of companies that use SCADA are also condominiums and water treatments.

Condos monitor and control lights, doors, water levels and alarms.

Usually an HMI or a computer is placed in a central and connected to the equipment.

Communication protocols

Communication protocols, either via serial or ethernet, were standardized. Sometimes there are specific formats for each equipment. But in general, the communication protocols were defined as MODBUS RTU, MODBUS TCP, PROFIBUS, PROFINET, ETHERNET/IP, BACNET, etc.

The communication protocols are the formats of the bytes sent and received by the equipment. Contains equipment data and address information for registers.

The types of equipment used to communicate with SCADA are usually programmable logic controllers, called PLCs. But they can have specific devices.

Communications links are usually configured networks.

Network data communication is the structure of information sent and received by the SCADA system. The network can be through serial structure or ethernet. The data contains the values of equipment information (temperature, count, energy, etc.).

Example of how to configure MODBUS RTU using SCADA: