SCADA monitoring

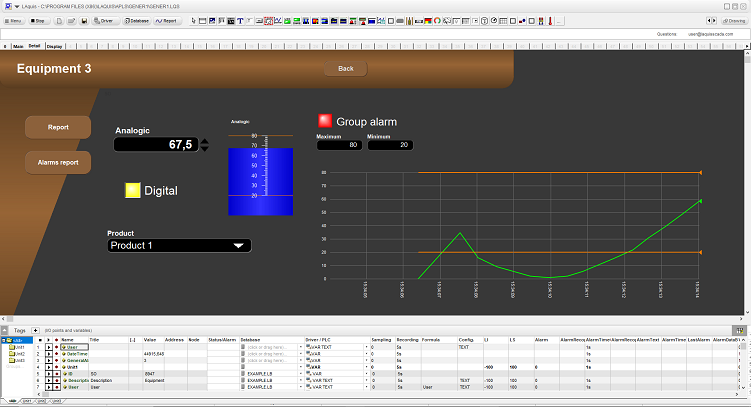

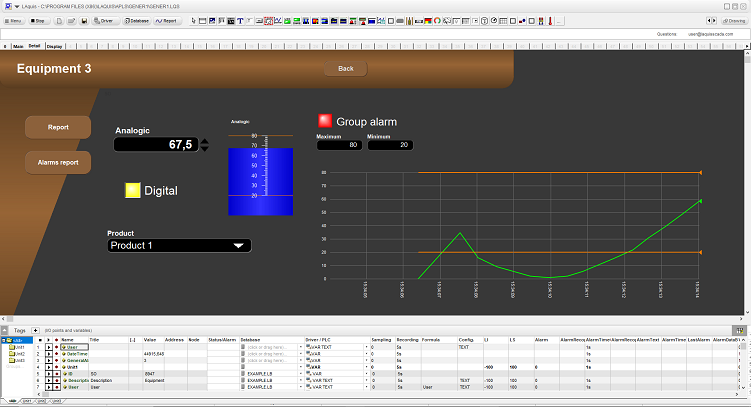

SCADA Monitoring reads the sensors, shows the data on the user interface and generates a historical log with reports.

The SCADA software is used to track and trace the information.

The system follows and can also optionally control in some cases, for example switching on and off relays or changing the voltage.

The sensors communicate with the software through communication protocols. They can be serial, ethernet or WIFI. Some protocols can be MODBUS.

SCADA monitoring, using the IOT (internet of things) framework has many forms.

Telemetry can also be used via internet, GSM, SMS, etc. A protocol currently used for telemetry over the internet is MQTT.

It depends on the specific technology for each case.

Various types of information can be monitored: voltage, temperature, power, levels, counts, etc.

Industrial automation sometimes has the need to monitor in real time. Generating alarms when they exceed the limits.

Management, in the SCADA monitoring, which monitors and controls the system, is important to maintain production quality and safety in real time.

The production count also follows the quality and time.

In the case of water treatment, levels and pumps are monitored in real time.

Electrical systems must be configured correctly for durability.

SCADA monitoring is used for Programmable Logic Controller (PLC) or other equipment. Devices, when they have serial or TCP communication, can allow you to make equipment information available. The data collected can be stored.

Several areas of SCADA monitoring. Electrical power, water treatment, wind speed, pressure, temperature, counts, alarms, etc.

Control systems in industries have various types of monitoring, using the user interface. Sensors, available on equipment, receive the signals in real time. The equipment sends the information as servers.

Automation, helps in industry control. Real -time data communication are usually associated with computers. In computers are installed the SCADA software for monitoring. The computer network is important for SCADA monitoring. Computer security assists real -time automation. The data, can be accompanied in real time, or stored in a given bank. In real time, using the user interface, the data can be placed on displays, or accessed via web.

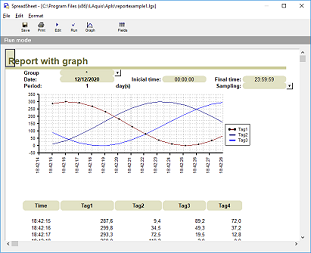

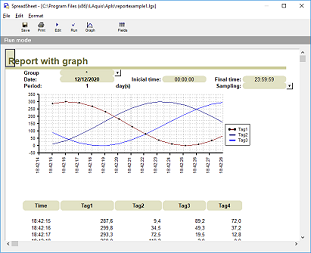

In the case of the database, they can be analyzed in status reports. Sometimes they are placed in TXT or CSV files.

A SCADA monitoring statistics is important. Main for verification of the quality of the process. When the given are production count, the speed, quantity and quality is usually followed. When the data is temperature, voltage, power, level, speed and pressure, sometime is used, for alarm test, when values exceed the limits. SCADA monitoring checks the alarms in real time with the user interface or via database. A quantity and alarm level is important for monitoring the quality of industrial production. The SCADA software to SCADA monitoring. Uncertainty calculator for calibration and metrology. SCADA temperature for monitoring.

Download LAquis SCADA software

The SCADA software is used to track and trace the information.

The system follows and can also optionally control in some cases, for example switching on and off relays or changing the voltage.

The sensors communicate with the software through communication protocols. They can be serial, ethernet or WIFI. Some protocols can be MODBUS.

SCADA monitoring, using the IOT (internet of things) framework has many forms.

Telemetry can also be used via internet, GSM, SMS, etc. A protocol currently used for telemetry over the internet is MQTT.

It depends on the specific technology for each case.

Various types of information can be monitored: voltage, temperature, power, levels, counts, etc.

Industrial automation sometimes has the need to monitor in real time. Generating alarms when they exceed the limits.

Management, in the SCADA monitoring, which monitors and controls the system, is important to maintain production quality and safety in real time.

The production count also follows the quality and time.

In the case of water treatment, levels and pumps are monitored in real time.

Electrical systems must be configured correctly for durability.

SCADA monitoring is used for Programmable Logic Controller (PLC) or other equipment. Devices, when they have serial or TCP communication, can allow you to make equipment information available. The data collected can be stored.

Several areas of SCADA monitoring. Electrical power, water treatment, wind speed, pressure, temperature, counts, alarms, etc.

Control systems in industries have various types of monitoring, using the user interface. Sensors, available on equipment, receive the signals in real time. The equipment sends the information as servers.

Automation, helps in industry control. Real -time data communication are usually associated with computers. In computers are installed the SCADA software for monitoring. The computer network is important for SCADA monitoring. Computer security assists real -time automation. The data, can be accompanied in real time, or stored in a given bank. In real time, using the user interface, the data can be placed on displays, or accessed via web.

In the case of the database, they can be analyzed in status reports. Sometimes they are placed in TXT or CSV files.

A SCADA monitoring statistics is important. Main for verification of the quality of the process. When the given are production count, the speed, quantity and quality is usually followed. When the data is temperature, voltage, power, level, speed and pressure, sometime is used, for alarm test, when values exceed the limits. SCADA monitoring checks the alarms in real time with the user interface or via database. A quantity and alarm level is important for monitoring the quality of industrial production. The SCADA software to SCADA monitoring. Uncertainty calculator for calibration and metrology. SCADA temperature for monitoring.

Download LAquis SCADA software